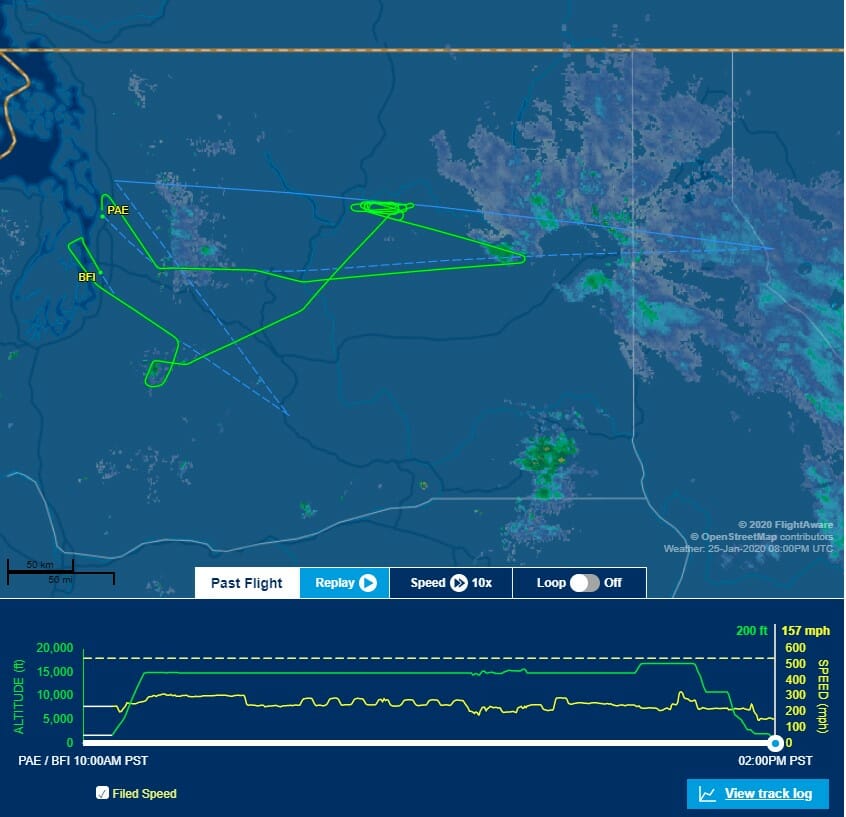

Today marked a milestone for the Boeing 777X program. I was watching the live stream to see the 10:10 am take off from runway 34L at Paine Field (PAE). The aircraft completed a four-hour low-speed functionality test for this initial test flight.

First Test Flight

This first flight was a basic functionality test flight at low speed and low altitude. The crew consisted of just the pilot and copilot as a full complement of engineers will be added in subsequent flights. Here is the test route for today’s maiden test flight.

The first flight required the aircraft to keep the flaps and landing gear extended. For this, a slow speed flight plan is required keeping the aircraft under 300 knots. The flight altitude was at 15,000 feet with an accent late in the flight.

The aircraft landed at 2:00 pm PST at Boeing Field (BFI) in Seattle on runway 14 Right. From there, it taxied on taxiway Bravo to the hangar.

Why This Test Is So Critical

First things first, Boeing needed some good news and a morale booster. Thousands of employees were on hand to witness this first test flight.

Even though the 777 has been flying for over 20 years, there are new features and systems onboard that need testing prior to FAA certification. The wings feature retractable wingtips that must be extended and locked prior to the takeoff roll. On the landing roll, the computer retracts the wingtips when the landing speed reaches 50 knots.

Another new feature to be tested is the new GE 9X engines. These new engines are the largest production turbofan engines with the fan disk measuring 11 feet in diameter.

What Is Involved In The Testing Program

Before the Boeing 777X can receive an airworthiness certificate from the FAA, it will have to undergo an extensive testing program. The testing programs consist of three phases:

- Preparation – getting the aircraft ready for flight and doing ground testing on engines and taxi tests,

- Execution – flying the aircraft like today to check for anomalies and flight handling characteristics and

- Data collection and evaluation – this is where engineering looks at the actual flight data to see if it matches the computer models used for design.

Testing results from the flight crew are evaluated for a variety of parameters:

- Static and dynamic pressures,

- Vibrations,

- Aircraft handling,

- Performance of control surfaces and

- Engine performance.

You can see in the photo above the pressure monitoring unit is trailing the top of the tail. The static and dynamic pressures across the entire aircraft are monitored for evaluation. These evaluations are used to verify that computer data used during the design phase are correct.

What’s Next For The Testing Program

The testing program for a new aircraft could take years. Since this aircraft is a follow-on to an existing program, the testing program should only take months to complete. After a few flights with just the pilots, an engineering team will be on board monitoring the test stations aboard the aircraft. There is no passenger interior installed, there are the test stations and water barrels. The water barrels are used if there is a weight and balance issue with a test flight. The testing phases will include:

- Airworthiness testing,

- Systems testing,

- Performance testing and

- FAA certification testing to obtain the required airworthiness certificate for passenger flights.

A Milestone For The 777X Program

Today is just the beginning of the flight testing program. There will be months of flight tests ahead with each test getting more involved in the flight envelope. There will testing to the extremes for extreme temperature operations, testing flight parameters such as rejected takeoff, wet landing to pressure and structual tests like a tail strike due to over-rotation on takeoff.

Today’s flight was a success. Now the real work begins so this aircraft can receive FAA certification to enter airline service.