I thought my first story on this Alaska Airlines flight 1282 plug door story was a one-and-done. Hang on, the saga continues as part three will be a take on what the Federal Aviation Administration (FAA) wants for answers from Boeing and corrective action. If you missed the previous posts, you can read part one here and part two here.

The FAA

Before I get into this story’s nuts and bolts, let’s look at the FAA. What is the FAA? The FAA is a Federal Agency that has two missions:

- To promote aviation and

- To ensure safety in aviation.

The problem is that sometimes, it is difficult to keep these objectives separate. In the past, there have been incidents and accidents where the FAA was slow to require changes or were far too lenient in dealing with aviation issues.

One of the problems with the FAA is that they do not have enough inspectors to evaluate who aircraft are built. Simply put, the Federal Government can’t afford to pay the wages that the industry pays for like positions. The FAA requires aircraft manufacturers to submit how they intend to inspect aircraft under construction. They more or less leave it up to the manufacturers to police their own inspections.

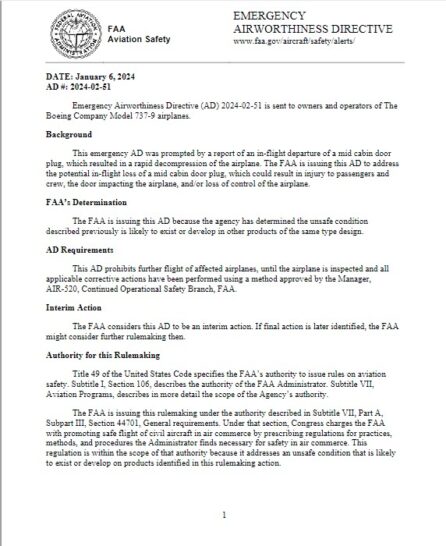

The Immediate FAA Action

Right after the incident aircraft suffered the door loss and decompression, the FAA was quick to issue and Emergency Airworthiness Directive (EAD) for U. S. airlines operating the 737 MAX9 aircraft.

What this EAD says is that operation of 737 MAX9 aircraft are prohibited until and inspection and corrective actions have been performed. However, this was paragraph is vague because it doesn’t state what the method approved by the Manger is.

AD Requirements

This AD prohibits further flight of affected airplanes, until the airplane is inspected and all

applicable corrective actions have been performed using a method approved by the Manager,

AIR–520, Continued Operational Safety Branch, FAA.

The FAA backtracked and issued a revised EAD that spelled out the process and let the aircraft return to service after the approved work was completed. Both United and Alaska Airlines hoped to get most of their aircraft back in the air by Saturday, January 13, 2023.

Here are the changing steps the FAA has taken from oldest to newest:

Updates on Grounding of Boeing 737 MAX 9 Aircraft

This information is preliminary and subject to change.

This incident should have never happened and it cannot happen again. FAA formally notified Boeing that it is conducting an investigation to determine if Boeing failed to ensure completed products conformed to its approved design and were in a condition for safe operation in compliance with FAA regulations. This investigation is a result of an incident on a Boeing Model 737-9 MAX where it lost a “plug” type passenger door and additional discrepancies. Boeing’s manufacturing practices need to comply with the high safety standards they’re legally accountable to meet. The letter is attached.

The safety of the flying public, not speed, will determine the timeline for returning the Boeing 737-9 Max to service.

January 9, 2024

Every Boeing 737-9 Max with a plug door will remain grounded until the FAA finds each can safely return to operation. To begin this process, Boeing must provide instructions to operators for inspections and maintenance. Boeing offered an initial version of instructions yesterday which they are now revising because of feedback received in response. Upon receiving the revised version of instructions from Boeing the FAA will conduct a thorough review.

The safety of the flying public, not speed, will determine the timeline for returning the Boeing 737-9 Max to service.

January 8, 2024

The FAA has approved a method to comply with the FAA’s Boeing 737-9 emergency airworthiness directive, and it has been provided to the affected operators.

The FAA’s priority is always keeping Americans safe. In that spirit, Boeing 737-9 aircraft will remain grounded until operators complete enhanced inspections which include both left and right cabin door exit plugs, door components, and fasteners. Operators must also complete corrective action requirements based on findings from the inspections prior to bringing any aircraft back into service.

The FAA will continue to support the National Transportation Safety Board’s investigation into Alaska Airlines Flight 1282. The NTSB is in charge of the investigation and will provide any updates.

January 7, 2024

The FAA’s first priority is keeping the flying public safe. We have grounded the affected airplanes, and they will remain grounded until the FAA is satisfied that they are safe.

January 6, 2024

The FAA ordered the temporary grounding of certain Boeing 737 MAX 9 aircraft operated by U.S. airlines or in U.S. territory.

“The FAA is requiring immediate inspections of certain Boeing 737 MAX 9 planes before they can return to flight,” FAA Administrator Mike Whitaker said. “Safety will continue to drive our decision-making as we assist the NTSB’s investigation into Alaska Airlines Flight 1282.”

The Emergency Airworthiness Directive (EAD) requires operators to inspect affected aircraft before further flight. The required inspections will take around four to eight hours per aircraft.

The EAD will affect approximately 171 airplanes worldwide.

Wait Just A Minute

Yesterday, the FAA changed their minds again. It looks like they now want an investigation into how Boeing assembles the door plug. Now the FAA is focusing on the area that should be at the heart of the problem, quality control. It was just last month when alarm bells at the FAA rang concerning loose rudder bolts in the 737 MAX aircraft. Do we have an earlier problem with loose bolts on the 737 MAX aircraft? Does Boeing have a serious safety culture problem?

FAA Closely Monitoring Inspections of Boeing 737 MAX Airplanes

The FAA is closely monitoring targeted inspections of Boeing 737 MAX airplanes to look for a possible loose bolt in the rudder control system.

Under consultation with the FAA, Boeing has issued a Multi-Operator Message (MOM), urging operators of newer single-aisle airplanes to inspect specific tie rods that control rudder movement for possible loose hardware.

The FAA will remain in contact with Boeing and the airlines while the inspections are underway. The agency is asking the airlines to work through their approved Safety Management Systems to identify whether any loose hardware has been detected previously and to provide the agency with details on how quickly these two-hour inspections can be completed.

The FAA will consider additional action based on any further discovery of loose or missing hardware. Boeing recommended the inspections after an international operator discovered a bolt with a missing nut while performing routine maintenance on a mechanism in the rudder-control linkage. The company discovered an additional undelivered aircraft with a nut that was not properly tightened.

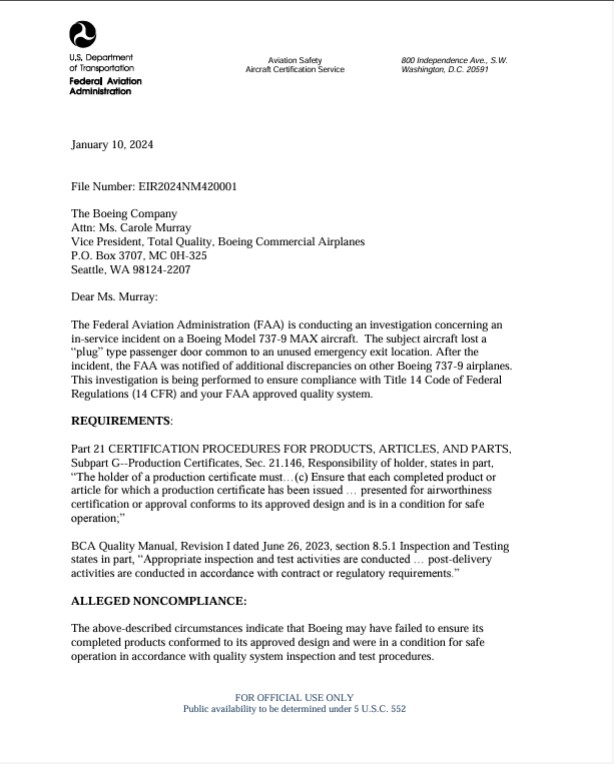

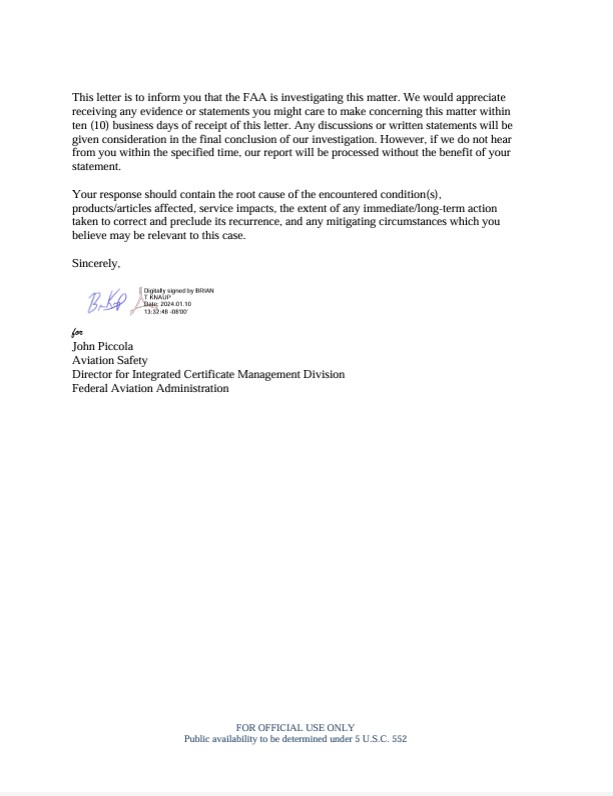

On Wednesday, the FAA sent a letter to Carole Murray, VP Total Quality at Boeing Commercial Airplane Company. The FAA is putting Boeing on notice that they are now under investigation for this new problem. Yes, it looks like the real problem of quality control is now being looked at.

Aircraft manufactures have written process and procedure manuals that cover every aspect of aircraft assembly. Is Boeing following their own processes and procedures? This is the point of the FAA letter and investigation:

REQUIREMENTS: Part 21 CERTIFICATION PROCEDURES FOR PRODUCTS, ARTICLES, AND PARTS, Subpart G–Production Certificates, Sec. 21.146, Responsibility of holder, states in part, “The holder of a production certificate must…(c) Ensure that each completed product or article for which a production certificate has been issued … presented for airworthiness certification or approval conforms to its approved design and is in a condition for safe operation;” BCA Quality Manual, Revision I dated June 26, 2023, section 8.5.1 Inspection and Testing states in part, “Appropriate inspection and test activities are conducted … post-delivery activities are conducted in accordance with contract or regulatory requirements.”

ALLEGED NONCOMPLIANCE: The above-described circumstances indicate that Boeing may have failed to ensure its completed products conformed to its approved design and were in a condition for safe operation in accordance with quality system inspection and test procedures.

When Will The 737 MAX9 Fly Again?

The return to commercial service date may be a moving target. First, it was completing the steps of the initial EAR from January 6. Then there was the revised directive and both United and Alaska thought they could complete all of the inspections by January 13. Now, we have the quality control investigation. Will that delay the MAX9 return to service until the investigation has been completed? I wouldn’t be surprised if the delay is indefinite until the FAA is satisfied that the aircraft is safe.

This Is Going To Cost Boeing

This episode is going to cost Boeing more than its reputation and standing in the aviation world. There will be financial costs for Boeing to pay. Boeing will have to pay for all of the repairs to bring all of the 737 MAX9 door plugs into safety compliance. What about the costs to the airlines? United has been cancelling an average of 200 flights per day and Alaska 150 flights per day. To be fair, not all of these cancellations are due to the 737 MAX9 groundings. It would be safe to say with 79 aircraft at United and 65 at Alaska, the majority of their flight cancellations are due to the groundings. Canceling flights is expensive for an airline. There is the lost revenue and lost customer confidence. These people have to get to their destinations somehow so another airline might get both their immediate business as well as future business. You can bet that the airlines are going to send Boeing a bill for their losses. The price of Alaska Airlines stock is also down. I would pursue Boeing for those losses too.

At The Airport

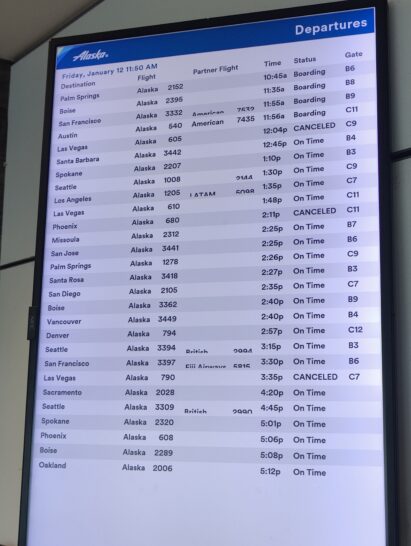

I am at Portland (PDX) Friday morning for a flight to Las Vegas (LAS). My flight is on a 737-800 and I will make it today and on time. Looking at the board, the other flights today to Las Vegas are cancelled because they are on the 737 MAX9 today.

Final Thoughts

When the 737 MAX9 returns to service may take longer than the airlines thought. Certainly, there is no excuse for an experienced aircraft manufacturer to deliver aircraft with loose or missing bolts. There seems to be a safety culture problem at Boeing and now the FAA is going to investigate why and how to correct safety deficiencies.

I am supposed to fly to JFK on January 20th on an Alaska Airlines 737 MAX9. Will my flight be affected? I’d really like to know sooner than later.