STORY UPDATE JANUARY 8, 2024 AT 11:30 AM (PST): Alaska Airlines has received inspection and repair instructions from Boeing (see below).

STORY UPDATE JANUARY 8, 2024 AT 2:30 PM (PST): Photo of the missing door plug found in a Portland OR area backyard.

Do you remember that grade-school riddle – When is a door not a door? When it is ajar. The missing plug door that affected Alaska Airlines 1282 on Friday is a similar proposition. There is a lot of confusion over what is an exit door and what is a plug door. In this post, I will cover:

- What is a door plug,

- Why is it there,

- What aircraft are affected (There may be a surprise here)

- How the door plug is installed so it should never come out and

- What is pressurization?

Special thanks to 737 pilot Chris Brady and his YouTube channel www.b737.org.co for some of the photos used in this post. I have included his video explanation is at the end of this post.

This is a multipart story. Your can read part 2 here and part 3 here.

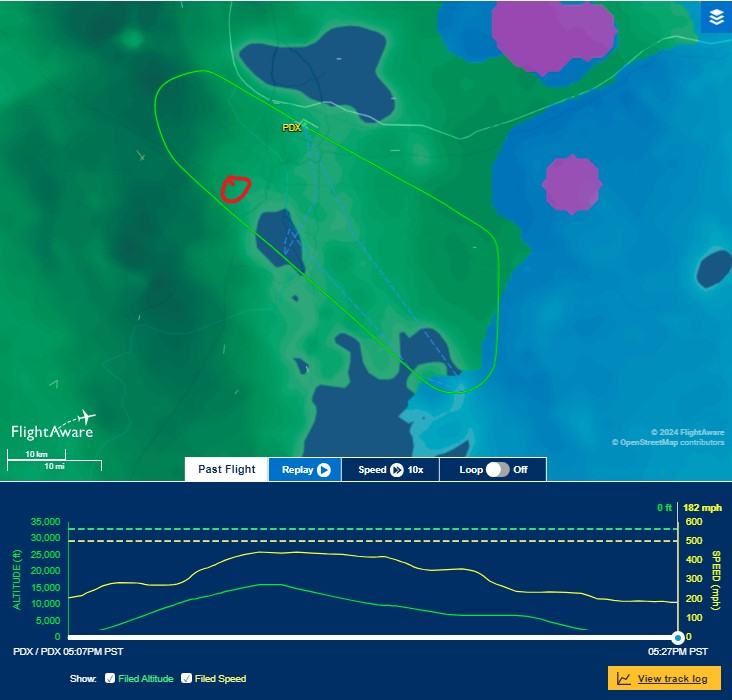

The Incident Flight

Alaska 1282 departed Portland (PDX) last Friday on a west departure from runway 28R. The flight to Ontario (ONT) required a left turn on the climb out to fly south to Ontario. It was during this turn approaching an altitude of 16,000 when the door plug blew out. Below is the ADS-B data from Flightaware with the approximate location where the door plug was found.

This was a low-decompression incident and at no time was the aircraft not capable of flying under control. The pilots called Portland Departure and declared an inflight emergency with a request to return to PDX. The flight crew flew a gradual decent to 10,000 and started their approach to PDX, landing on runway 28L. There were no serious injuries due to this event. There is no damage to the fuselage so it looks like the door plug just fell out.

The aircraft, a Boeing MAX 9, registration N704AL and MSN 67501 was delivered new to Alaska Airlines on October 31, 2023.

Pressurization

The first thing that we need to look at is what pressurization is. As you get higher in altitude, The air density gets thinner. The human body suffers a lack of oxygen above 13,000 feet in elevation so aircraft are pressurized to maintain a comfortable breathing experience at high altitudes. When you flight is cruising at 40,000 feet, your cabin air pressure is regulated at about 7,000 above sea level. When an aircraft is pressurized, the outside air is low pressure and the inside air is high pressure in a sealed cylinder that expands and compresses during pressurization.

It is when this seal is broken that depressurization occurs. If it is sudden, there can be an explosive decompression that can suck out anything that is not secured in the immediate area of the breach. In the case of Alaska 1282, a pressurization cockpit warning was present two days prior to the incident. The pressurization was so slight that the flight crews were able to override the automatic system to provide pressurization. This aircraft was restricted from overwater flights to Hawaii until the problem could be diagnosed and repaired.

This incident occurred at just below 16,000 feet of altitude. Had this occurred at full cruising altitude over 30,000, this would have been an explosive decompression incident and there would have been far more damage.

The Number of Emergency Exits On An Aircraft

The Federal Aviation Administration (FAA) has a rule that governs the number of exits on any aircraft. There is a functional requirement of evacuating all people within 90 seconds by using only half of the exits. The reason that the test is done using half of the exits is there may be some exits that are unusable during emergency egress. This is due to either a door damaged during a hard landing or the presence of a fuel fire at an exit making egress impossible. In the case of a water landing such as US Air 1549 where Captain Sully landed in the Hudson River, the rear exits were unusable because parts of the doors were below the water line.

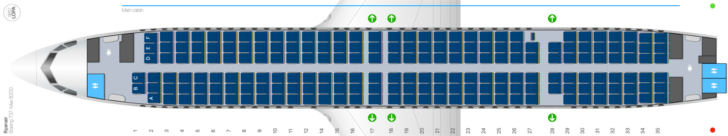

Airlines can order an aircraft with whatever number of seats that can legally fit in that aircraft. It is for this reason that the door plug exists on the Boeing 737 MAX 9. Most 737 MAX 9 aircraft have less than 190 seats so the standard four exit doors and four overwing exits will satisfy the emergency egress requirement. RyanAir orders their Boeing 737 aircraft with high-density seating where there are 199 seats or more. On the RyanAir aircraft, the plug door is an actual full-functioning exit door. All airlines flying the MAX 9, have opted for the less-expensive door plug instead of a full-functioning exit door because these aircraft have less than 190 seats. It is interesting to note that the airline that has the functioning exit door, RyanAir does not fly the 737MAX 9. They currently fly a high-density seating 737 MAX 8-200 with 199 seats. This unique MAX 8 aircraft does have full-functioning doors at row 28.

With the functioning door at row 28, seats 27F, 28A and 28F are eliminated to facilitate emergency egress. RyanAir plans to equip their 737MAX 10 aircraft with 230 seats.

Which Aircraft Are Affected?

This is where things really get interesting. The Boeing 737 has been in commercial service since 1967 with launch customer Lufthansa. Over the decades, the 737 has increased in size and updated features such as better-performance engines and state-of-the-art cockpit avionics. Currently, there are airlines flying theses aircraft:

- 737-300,

- 737-400,

- 737-500

- 737-700,

- 737-800,

- 737-900

- 737-900ER,

- 737 MAX 8 and

- 737 MAX 9.

Boeing is currently seeking FAA certification for the 737 MAX 7 and 737 MAX 10.

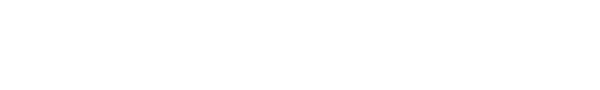

Everybody is talking about the 737 MAX 9 being the culprit with its plug-door option. I know for a fact that there are 737-900 ER aircraft that also has door plugs. The image below shows Alaska Airlines 737-900 ER with the door plug located at row 27.

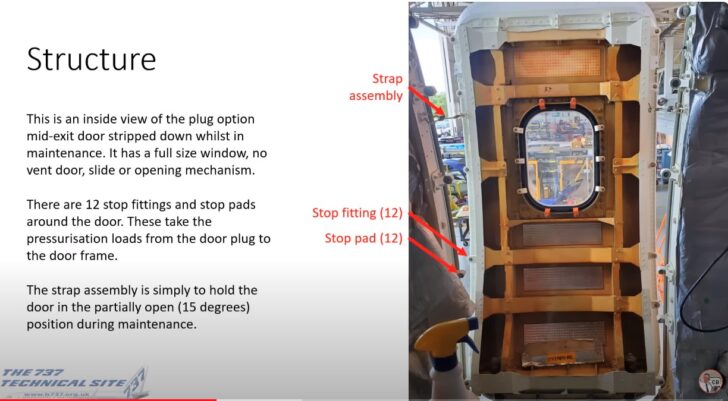

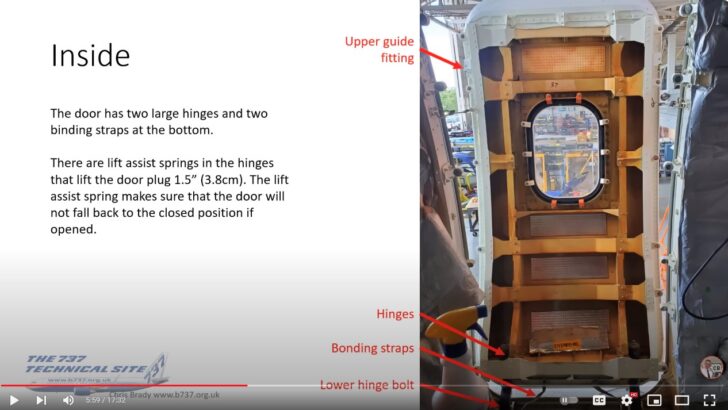

The Door Plug

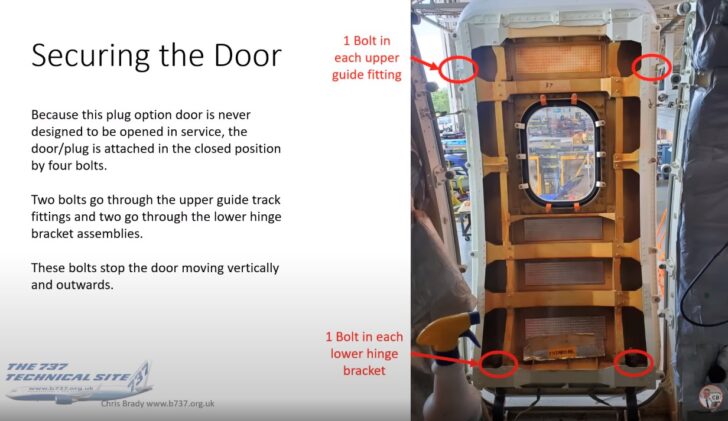

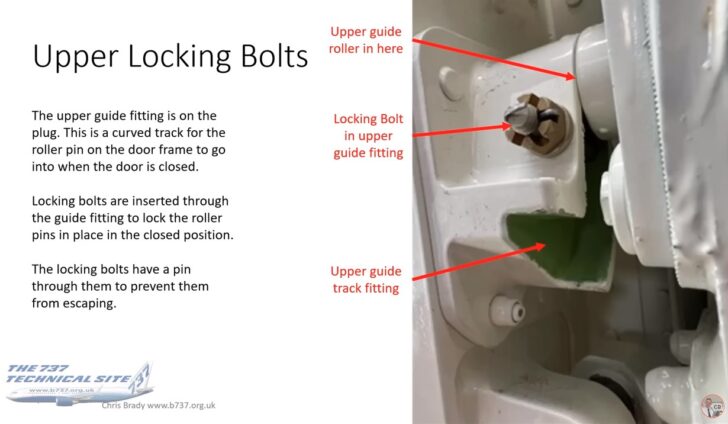

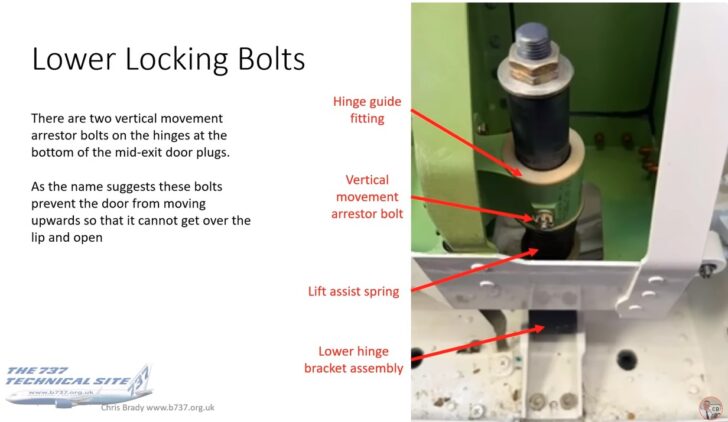

Both the 737 MAX 9 and 737-900ER were designed to have an extra pair of exit doors at row 27 if the seating capacity exceeded 189. Obviously, a fully-functioning door will cost a lot more than a door plug. The door plug is a low-cost option for aircraft with less than 190 seats. The plug consists of an outer panel and an interior panel sandwiched with insulation material to reduce noise. The plug is only meant to be removed during certain maintenance services. It is held in place with eight bolts where the nuts are secured by safety wire to prevent accidental loosening. Boeing does not make the fuselage for the 737 family of aircraft. They are manufactured by a contractor, Spirit AeroSystems of Wichita, KS and transported by rail to the Boeing 737 factory in Renton, WA.

Story update: Photo of the missing door plug found in a Portland OR area backyard.

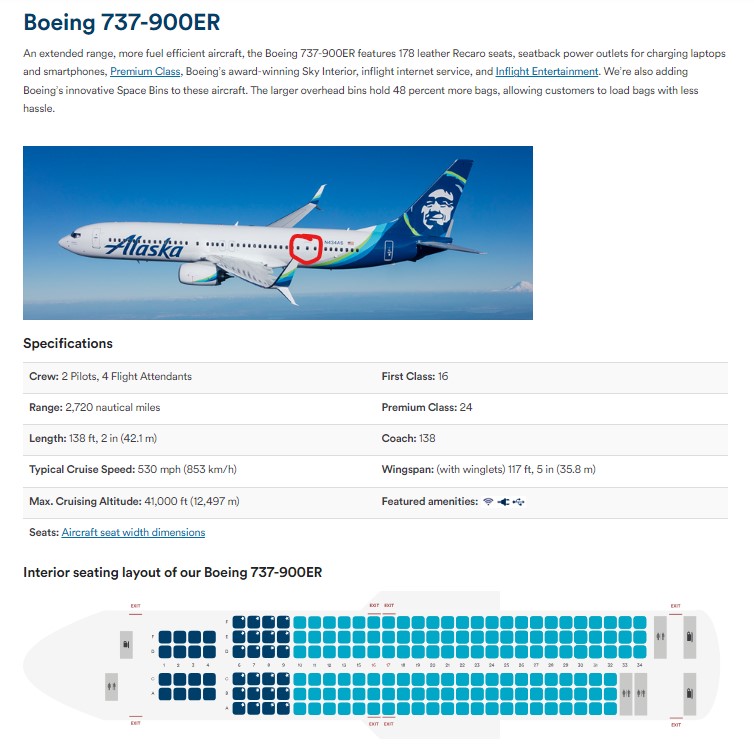

Response From The FAA and NTSB

The response was immediate. The FAA issued and emergency Air Worthiness Directive (AD) to ground all 737 MAX 9 aircraft until inspections and repairs are satisfactorily completed.

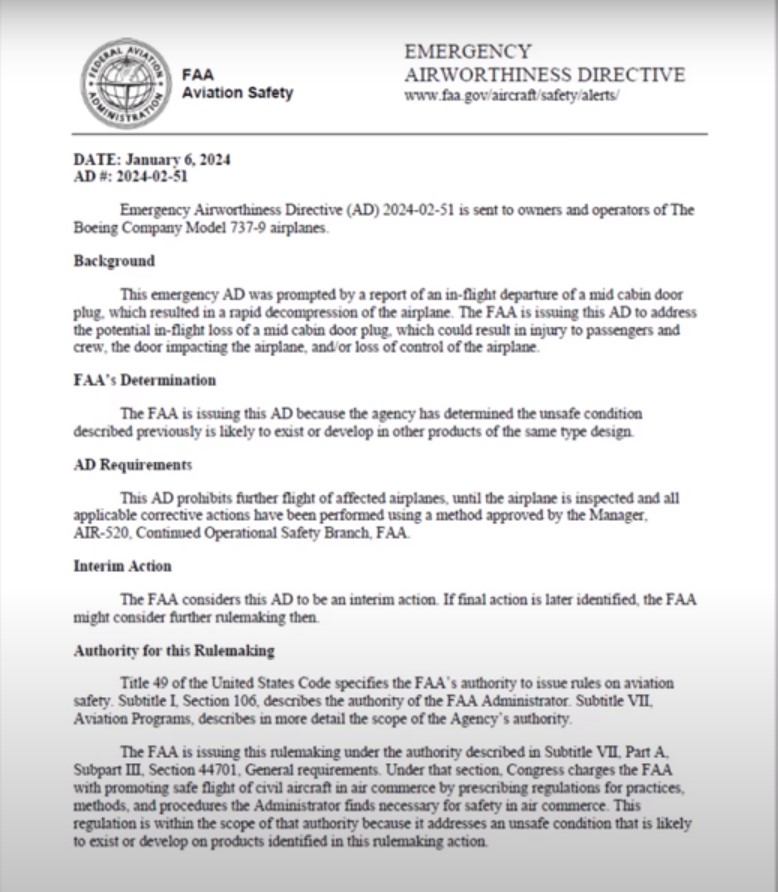

STORY UPDATE: Alaska Airlines issued a statement this morning on the memo that Boeing has issued approved inspection and repair instructions to operators of the 737MAX 9 aircraft.

Final Thoughts

Let me be clear, this incident is still under active investigation. There have been no other incidents with this aircraft type involving the door plug. There are eight bolts that have successfully secured the door plug to the fuselage. If I had to venture a guess, I would think that this might be a build quality issue. It seems to me that in the short time that this aircraft was in possession of Alaska Airlines, there was no need to open the panel where the door plug is located. This is an on-going investigation and details to come later.